Remove paper-based production logbooks, manual data entry and reporting on spreadsheets. Use a modern solution to help your team save time, produce faster and collaborate digitally.

Remove paper-based production logbooks, manual data entry and reporting on spreadsheets. Use a modern solution to help your team save time, produce faster and collaborate digitally.

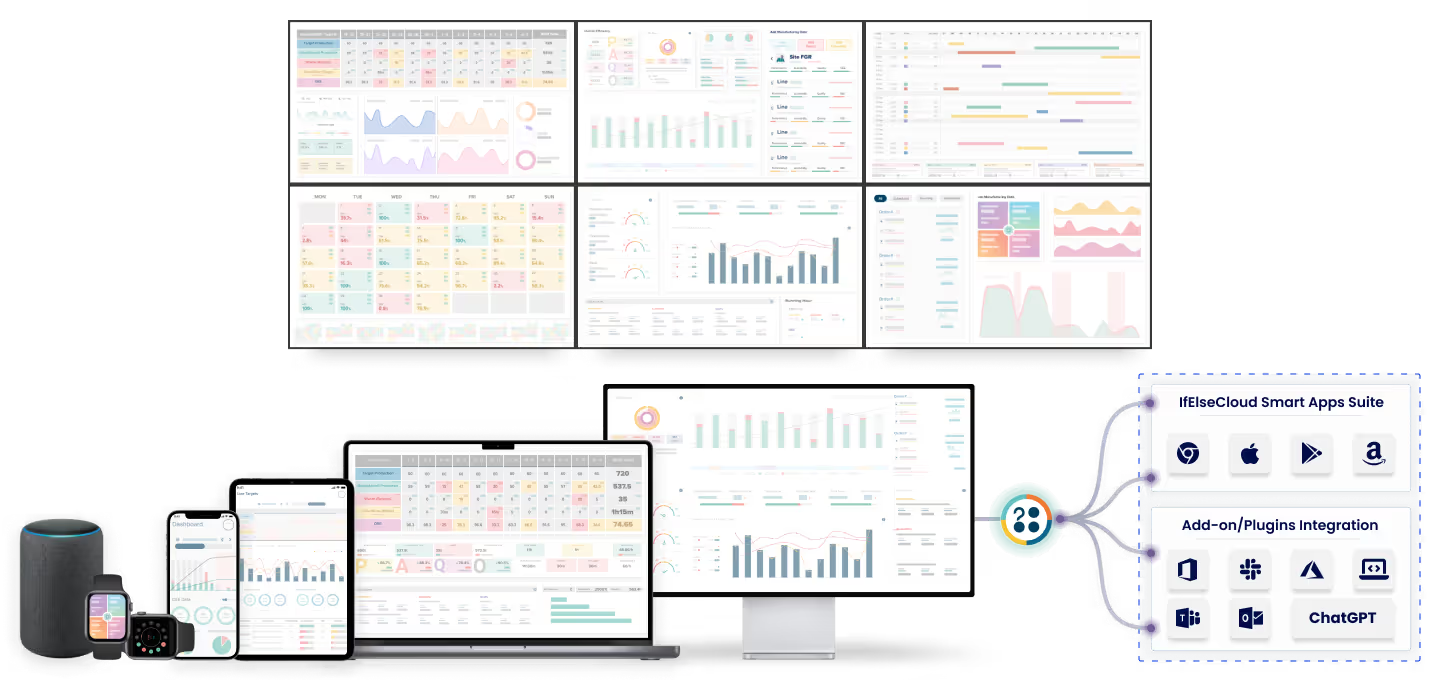

Replace whiteboards with video walls, clipboards with tablets, papers based reports with digital reports on phones and Microsoft Teams.

Bring your teams together and improve collaboration with our integrated Manufacturing Execution System (MES) and advanced analytics tools.

Manage raw materials, BoM, stock for finished or semi-finished goods, suppliers, and allocate or forecast consumption based on the production.

Create Visio-style workflows assigning machines, raw materials, and workforce. Auto-create and schedule the entire production sequence as jobs.

Import jobs from ERP, create from workflows, on-demand, recurring or rework. Create the schedule and monitor the real-time status.

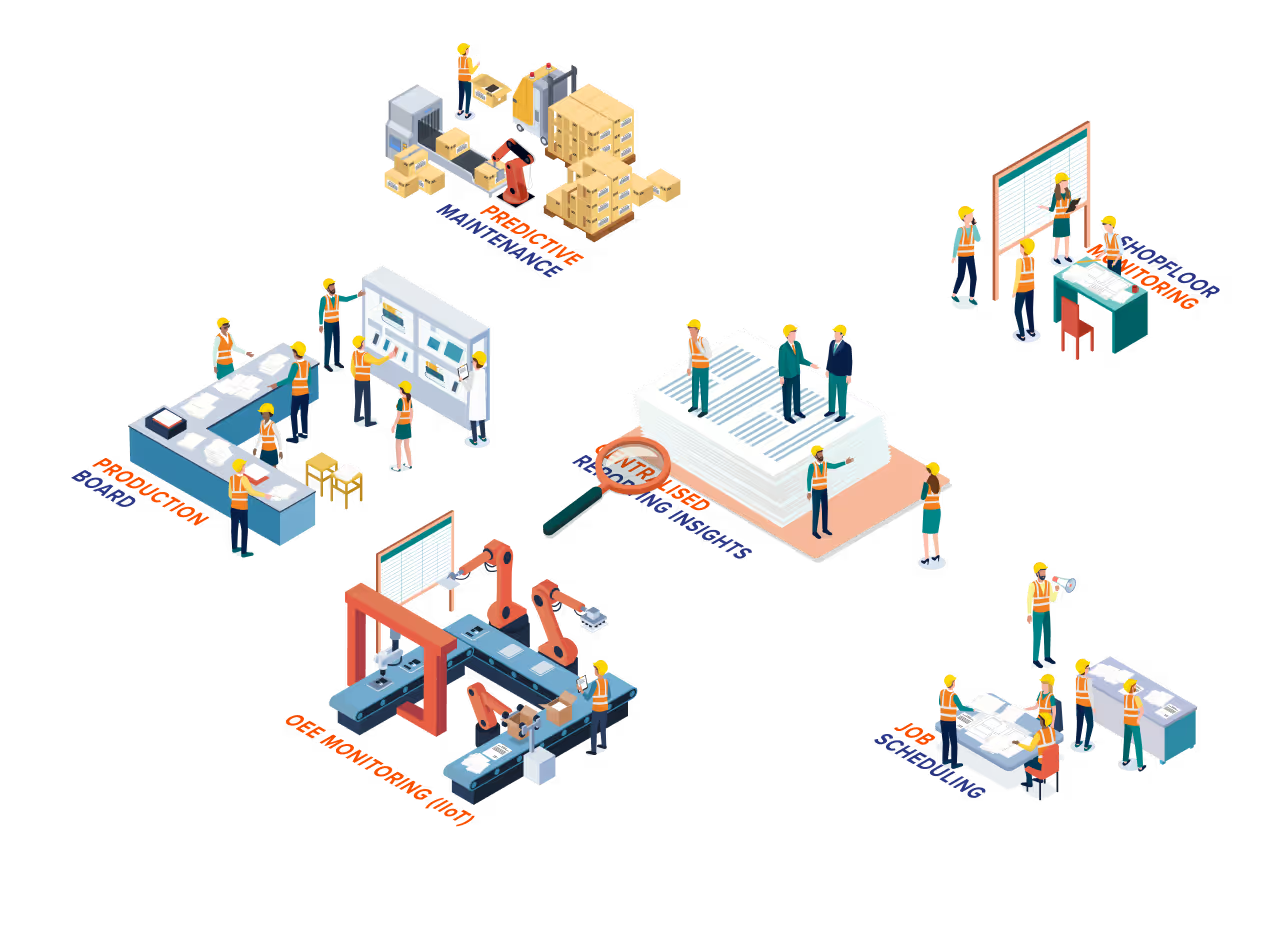

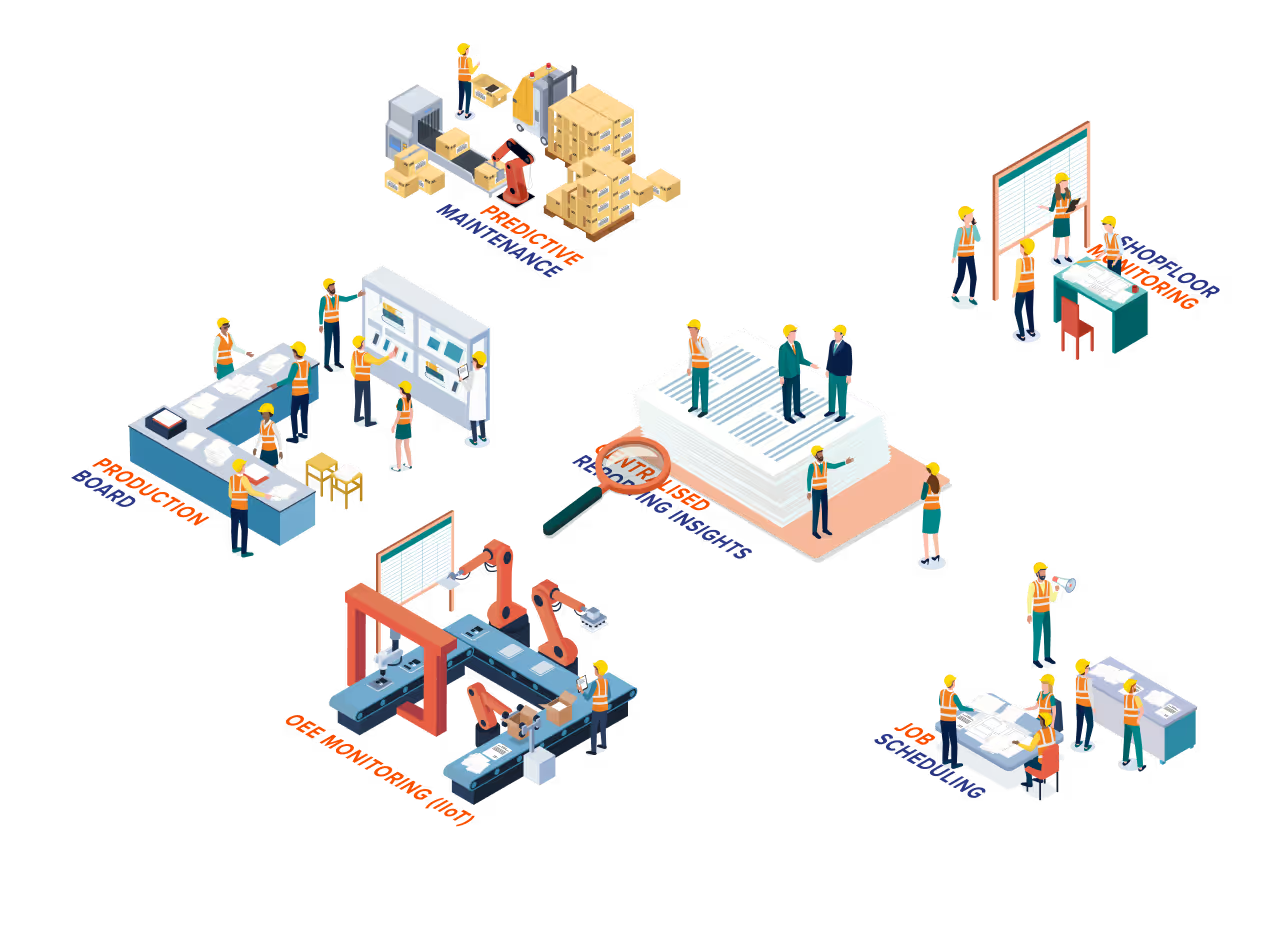

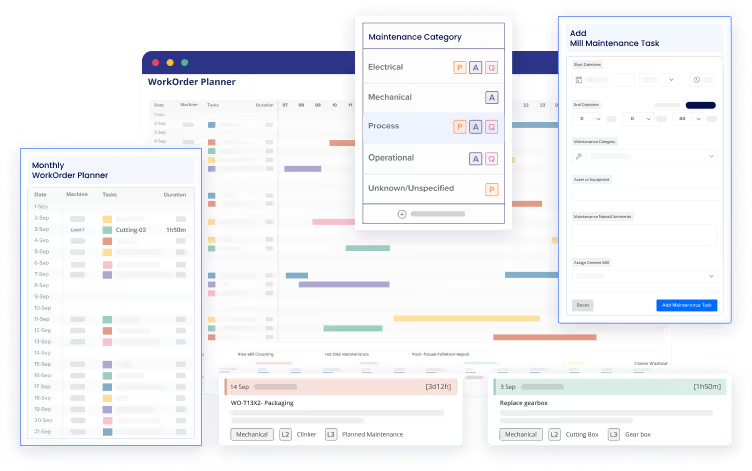

Monitors machines, jobs, production rate and completion with digital production boards. Use workforce smart apps for a process paperless process.

Embed quality SoP in the production sequence. Add the QA checkpoints, static or based on SKU—Auto-attach QA data, notes/images with the jobs.

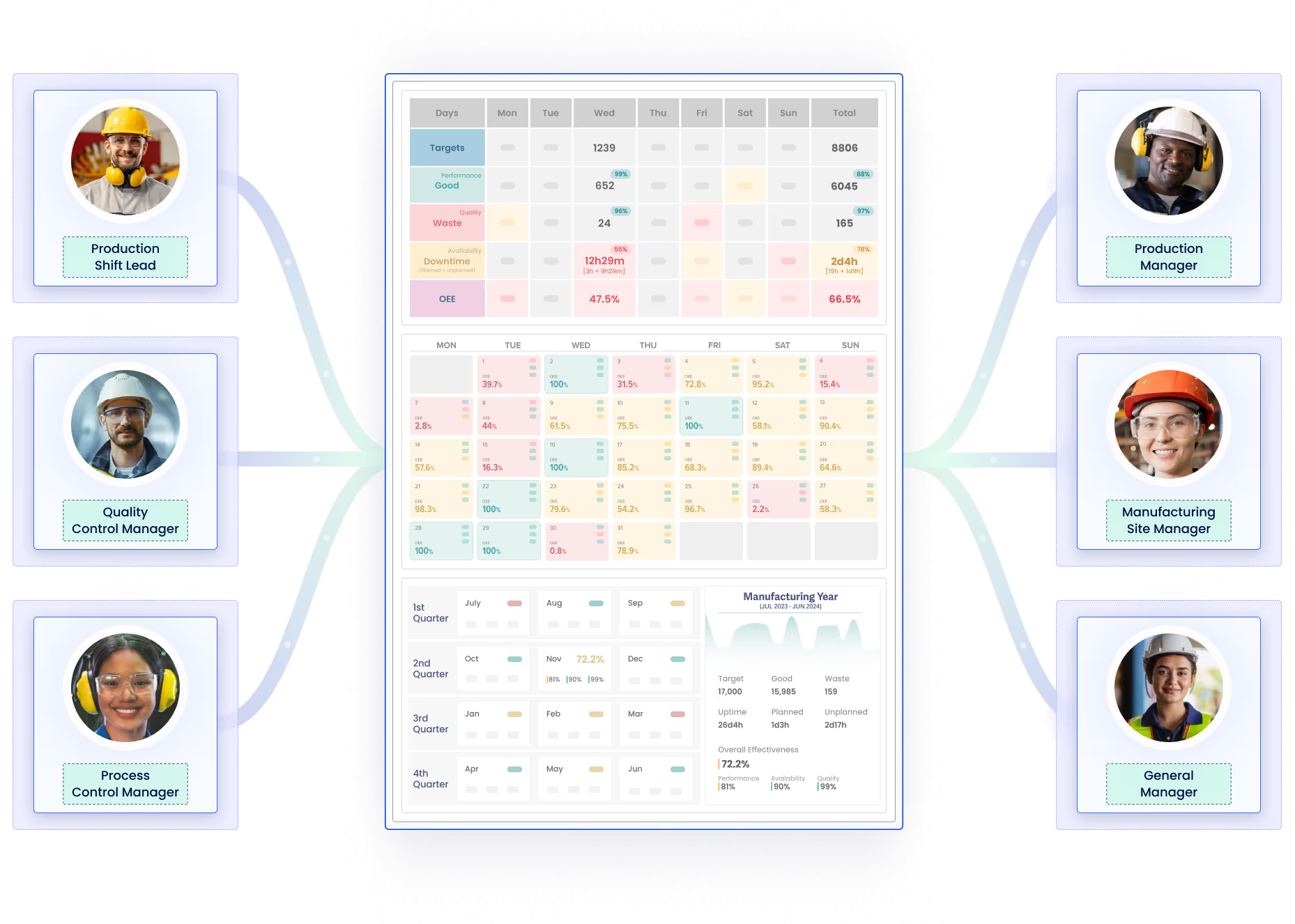

Use SoPs to schedule one-off or recurring machine/line downtime. Auto-update the production timeline, capacity, utilization and MTBF/MTTR.

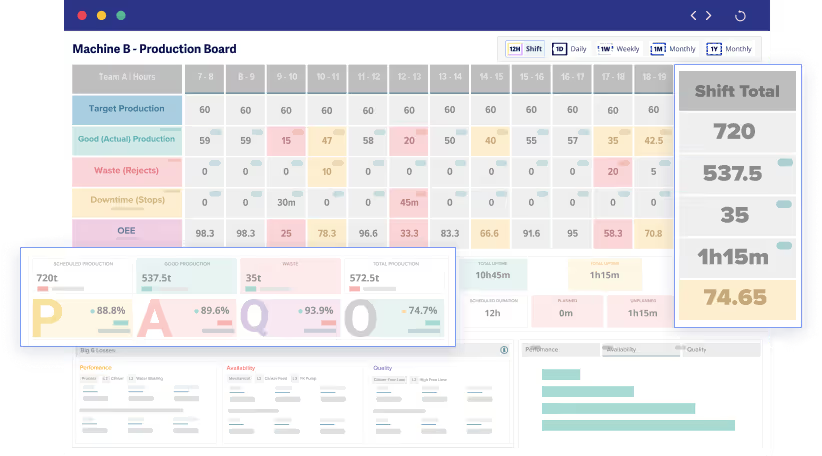

Real-time dashboards to analyze workforce performance, machine availability, product quality and OEE of each line or the entire factory.

Assign workforce to production workflow or jobs based on skills or ID. Auto-measure all KPIs, performance failures and unit completion.

A high-level overarching layer for project/program managers. Manage discrete production, supply/logistics, resourcing, or transformation projects.

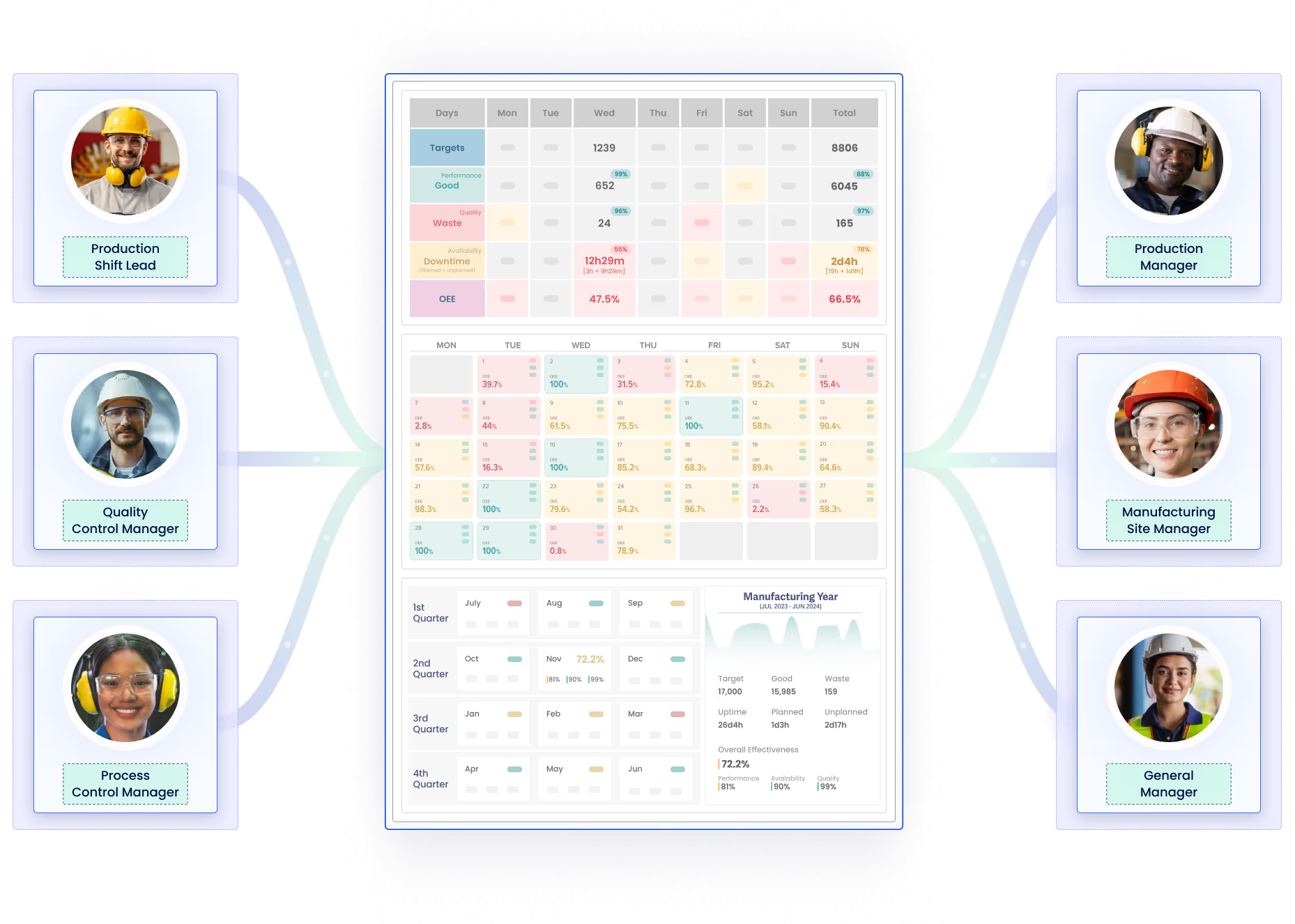

View on real-time dashboards or auto-create shift, daily, weekly, monthly, quarterly or annual reports on 200+ insights across your manufacturing.

Create production workflows, manage raw materials, finished and unfinished goods and plan what needs to be produced and how and forecast the required resources for the plan.

Raw Materials

BoM

Manage Stocks

Workforce Resources

Maintenance

Consumables

Projects

Machines

Production Orders

Rework

Allocate material, machines, workforce and consumables required to complete the production efficiently. Smart scheduling suggestions to run the most optimal job schedule.

Production Workflows

Work Orders

MTO

MTS

SKU Management

Workforce

Material Allocation

Maintenance

Run the Shopfloor digitally without paperwork. Collect machine data automatically. Workforce can use smart device applications for production updates, QA checks and updating failure

Shopfloor

Quality Control

Production Run

Update Jobs

SOPs

Log Waste

Log Downtime

Shifts Management

Update Stock

Check production completion, jobs estimated end timings, OEE, QA failure reasons, updates from shopfloor workforce on the Digital Production Board for Shopfloor. Promoting transparency and easy shift changeover.

Overall Efficiency (OEE)

Performance

Availability

Quality

Production Rate

Jobs Estimates

Machine Failure

Operations Tasks

Get automated reports from all manufacturing areas delivered for every duration. Enable a data-driven meeting and decision-making process. Use the power of ML and AI to make smarter decisions. Attract younger workforce and remove manual reports.

Shift

Daily

Weekly

Monthly

Annual

Jobs

Project Reports

Stock Updates

MTBF/MTTR

Carbon Footprints

Quality Failure

Performance Failure

Forecasting

Capacity

Utilization

84+

Shift

Insights

<1m

Create

Shift Reports

108+

Daily

Insights

<1m

Create

Daily Reports

160+

Monthly

Reports

<1m

Create

Monthly Reports

Create production workflows, manage raw materials, finished and unfinished goods and plan what needs to be produced and how and forecast the required resources for the plan.

Raw Materials

BoM

Manage Stocks

Workforce Resources

Maintenance

Consumables

Projects

Machines

Production Orders

Rework

Allocate material, machines, workforce and consumables required to complete the production efficiently. Smart scheduling suggestions to run the most optimal job schedule.

Production Workflows

Work Orders

MTO

MTS

SKU Management

Workforce

Material Allocation

Maintenance

Run the Shopfloor digitally without paperwork. Collect machine data automatically. Workforce can use smart device applications for production updates, QA checks and updating failure

Shopfloor

Quality Control

Production Run

Update Jobs

SOPs

Log Waste

Log Downtime

Shifts Management

Update Stock

Check production completion, jobs estimated end timings, OEE, QA failure reasons, updates from shopfloor workforce on the Digital Production Board for Shopfloor. Promoting transparency and easy shift changeover.

Overall Efficiency (OEE)

Performance

Availability

Quality

Production Rate

Jobs Estimates

Machine Failure

Operations Tasks

Get automated reports from all manufacturing areas delivered for every duration. Enable a data-driven meeting and decision-making process. Use the power of ML and AI to make smarter decisions. Attract younger workforce and remove manual reports.

Shift

Daily

Weekly

Monthly

Annual

Jobs

Project Reports

Stock Updates

MTBF/MTTR

Carbon Footprints

Quality Failure

Performance Failure

Forecasting

Capacity

Utilization

84+

Shift

Insights

<1m

Create

Shift Report

108+

Daily

Insights

<1m

Create

Daily Reports

160+

Monthly

Insights

<1m

Create

Monthly Report

A

Smart

Solution for

Smart

Manufacturing

Transform your workplace for a smarter, more efficient tomorrow.

What are the smart MES applications?

See Top Features for your Production Team

See Best Features for your Managers

See what's Most Valuable for the Leadership

Read more about these features

All benefits for Manufacturing Management

All benefits for the Top Leadership Team

The 3B Maturity Benchmark is a way to evaluate the performance of factories and plants, comparing them to the best-in-class, the average, and those that are behind in the manufacturing industry. It serves as a standard for the global manufacturing community.

Most companies (90%) struggle with the Technology aspect (aka Building Block), as per the SIRI Framework and RAMI 4.0 standards. These companies perform better in Process and Organization, which are the other two main blocks of the framework. In the Technology section, these companies score an average of 1 Band or less as compared to the other 9 dimensions, indicating that Technology has much room for improvement.

You have complete ownership and control over your data at all times. Our role is simply to analyze it and provide you with real-time analytics. That's the extent of our involvement in the transaction, nothing more or less.

Select from supported locations on Amazon Web Service data centers to host your Manufacturing data.

Host your manufacturing data on Microsoft Azure and select from data centers across the globe.

GCP is one of modern CSP and is fully supported to store your manufacturing data.

Information technology — Security techniques — Information security management systems.

Information technology — Security techniques — Security Controls based on ISO/IEC 27002 for Cloud Services

Resources and data hosted in multi-region and multi-cloud environment.

A platform built on the modern Enterprise Architecture with modern security.

Secured encrypted data-at-rest and access is via Private Links with CSPs.

Take a step closer to a paperless environment. Pilot it in your environment. Bring your team on the transformation journey.

Together, we'll embark on a journey to streamline processes, optimize efficiency, and craft a harmonious tale of manufacturing success.